Mar. 20, 2024

The loosening of bolts can have several effects during usage. One major consequence is that a loosened bolt may halt the entire production process, resulting in financial losses ranging from thousands to tens of thousands of yuan. Additionally, loose bolts pose safety hazards in factories. So, what are the main reasons for bolt loosening? Broadly speaking, there are two main reasons for bolt loosening: spontaneous loosening and fatigue loosening.

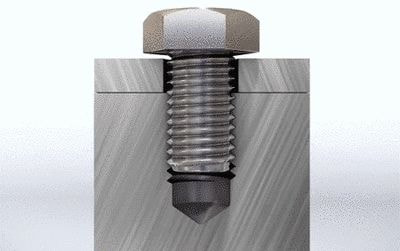

Bolts that are not tightened sufficiently or are falsely tightened have inadequate pre-tensioning force. If loosening occurs, the joint lacks sufficient clamping force to hold the various parts together. This can lead to lateral sliding between two components, causing unnecessary shear stress on the bolt, ultimately resulting in bolt fracture.

Tests on bolts subjected to vibration have shown that many small "lateral" movements cause the two parts of the joint to move relative to each other, while the bolt head or nut and the connected part also undergo motion. These repeated movements counteract the friction between the bolt and the connected part. Eventually, vibration will cause the threads on the bolt to "rotate loose," resulting in the joint losing its clamping force.

Engineers designing bolt tension allow for a break-in period, resulting in a certain loss of pre-tensioning force during this period. This relaxation is due to embedding between the bolt head and/or nut, the threads, and the mating surface of the connected part, and can occur in both soft materials (such as composite materials) and hard polished metals.

Many bolt joints include a thin and soft washer between the bolt head and the mating surface to seal the joint and prevent gas or liquid leakage. The washer itself also acts as a spring, rebounding under pressure between the bolt and the mating surface.

Over time, especially near high temperatures or corrosive chemicals, the washer may "creep," meaning it loses elasticity, resulting in a loss of clamping force.

Impact - larger impact loads exceed the frictional force when the bolt is pre-tensioned, causing sliding.

Dynamic or alternating loads from machinery, generators, wind turbines, etc., can lead to mechanical impacts - forces applied to the bolt or joint - causing relative sliding of the bolt.

Loose bolts are not just a headache. If joints are not quickly retightened, they may begin to leak fluids or gases, bolts may fracture, equipment may be damaged, or catastrophic accidents may occur.

In summary, "the best way to prevent loosening is to ensure sufficient pre-tensioning force, avoiding problems such as sliding and opening in the joint."

The above analysis shows that there are three reasons for loosening due to insufficient or reduced pre-tensioning force, so it is necessary to control the pre-tensioning force of bolts to control the risk of loosening.

As long as the pre-tensioning force meets the requirements and the clamping length is not too short (such as lk≥3d), even if there is a certain vibration load, the bolt generally will not self-loosen.

A good bolt connection will be designed with appropriate sizes and types of bolts and nuts, and specify the optimal tension to achieve the clamping force required to maintain the integrity of the connection.

In application, appropriate clamping force requires the tension (pre-tension) in each bolt to reach the correct level and remain at that level throughout the service life.

Therefore, maintaining proper tension on bolts is essential, and ultrasonic can be used to measure the axial force of bolts during design to ensure that the pre-tensioning force of bolts meets the design requirements. Zemax's ultrasonic axial force measuring instrument is specially designed to measure the axial force of bolts and also has a QR code function to track the axial force of the bolt in real-time.

Previous: None

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )